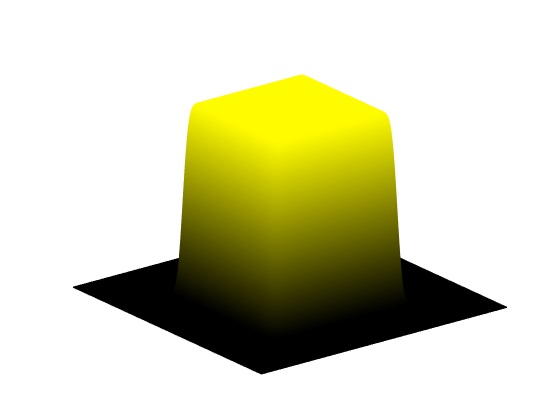

Top Hat Laser Beams are modified laser beams that exhibit a uniform irradiance profile with sharp edges. As this beam profile looks like a cylinder hat or Top Hat, this beam is known as a Top Hat Laser beam. It’s important to recognize that Top Hat Laser beams are typically not naturally occurring laser beams. In fact, almost all natural laser beams show a Gaussian-like irradiance profile. In a Gaussian profile, the irradiance level decreases from the central point towards the edges. As the value of the irradiance never truly reaches zero, there is an absence of sharp edges in the Gaussian profile.

In several laser beam applications, it is essential that the profile of the laser beam shows a homogeneous distribution of energy with clear edges. Transforming a Gaussian beam into a laser beam that’s top hat is important for those types of applications. A Gaussian profile i.e. when the pulse energy rises, the size of the spot also upsurges. In contrast, in a Top Hat laser beam profile, the area remains the same even after a pulse energy change.

Diffractive Optical Elements or DOEs are often used to exploit and shape laser beams by utilizing the wave nature of light. These optical components can transform the monochromatic light beams of the desired wavelength to top hat and other shapes.

Top Hat Laser Beam Shapers

Top Hat Laser Beam Shapers employ diffractive optical elements or DOEs to shape the laser beams and get an intensity spot that’s steady and uniform. Shaping the laser beams is important to get a specific irradiance distribution. A systematic arrangement is necessary to shape the laser beams. Typically, a lens system is placed after the DOEs. Focus lens can sit anywhere afterward the DOEs suitably so that the optical components’ far field gets reproduced at the focal plane of the lens. The optics and optics should have a diameter that is twice or more than the input laser beam’s diameter. The folding mirrors, lens, and other optics must be of high quality, i.e. diffraction-limited laser-grade optics.

Applications

From laser cutting and scribing to micromachining, diffractive beam shaping is useful in a variety of applications. For instance, the Top Hat laser beam profile becomes essential in fields where it is important to have laser beams that are coherent and can concentrate on a specific area. The Top Hat Laser beams can display a variety of different distributions depending on the design of the DOEs, including square, line, round, rectangular, and exotic shapes. Top Hat Laser beams have various crucial applications, such as laser cutting, laser scribing, including dias and electrodes, laser micromachining, including lithography, micro-drilling, kerf removal, and ablation, metrology of thin semiconductors, microscopy cytometry and light-sheet, and surface and annealing treatments. Typically, the intensity distribution is different in every application.

All the above-mentioned applications fulfill the main purpose of conserving a sharp border between treated and non-treated areas. When the laser energy changes, the treated area remains the same in these applications, allowing for consistent and stable laser processing. Therefore, whereas a substantial amount of energy gets lost in the Gaussian beam profile, in Top Hat Laser beams, the entire energy gets used.

No Comment! Be the first one.